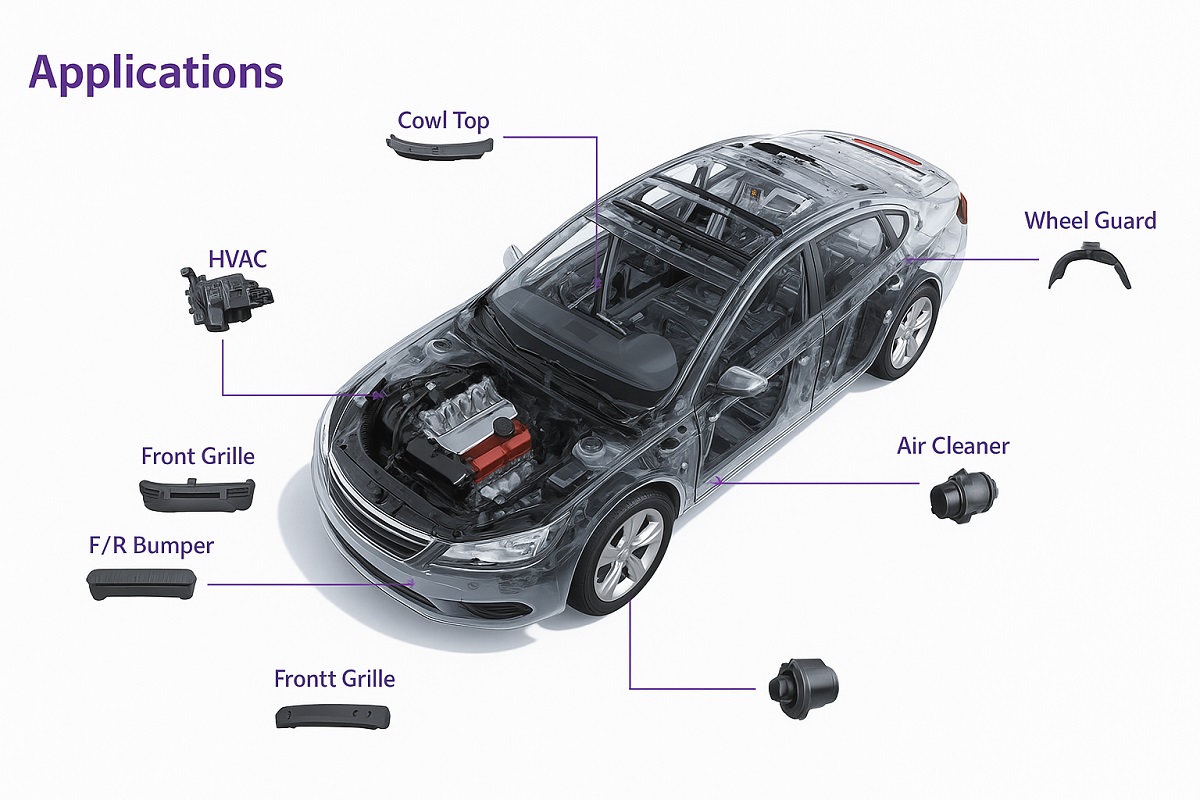

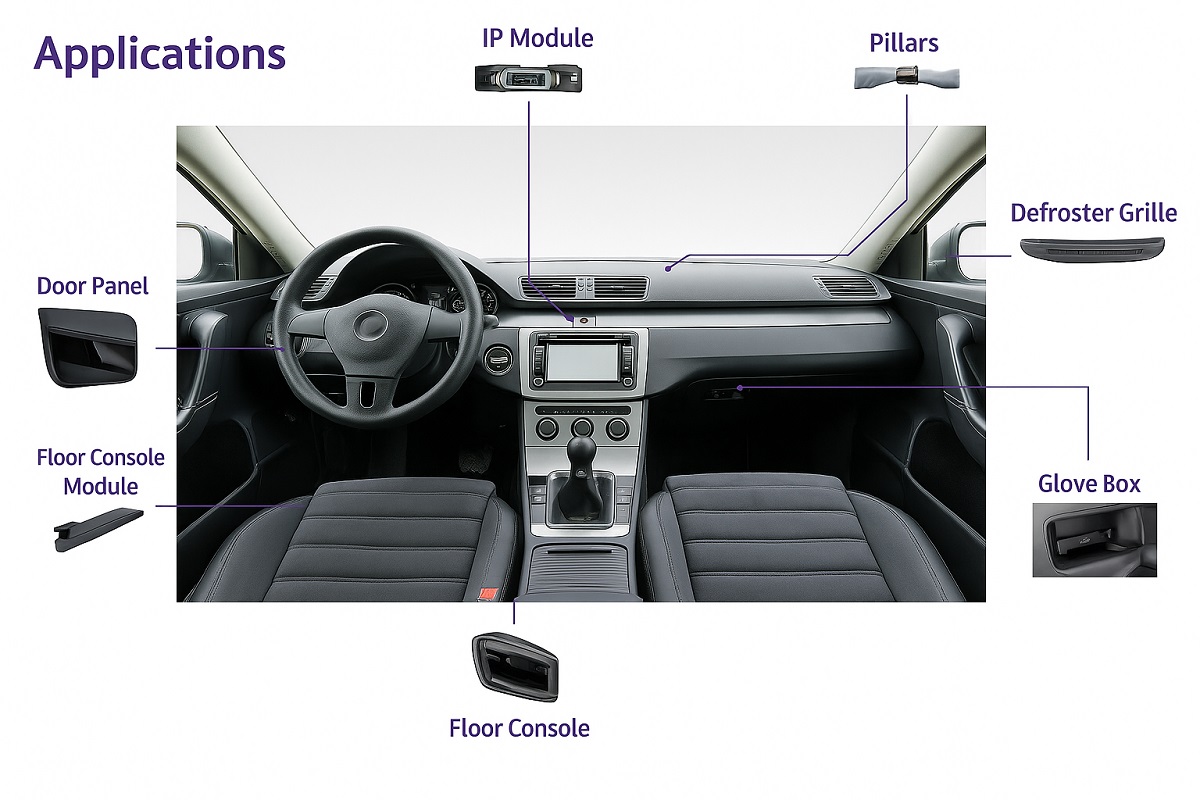

Hyosung Vina Chemicals’ polypropylene for automotive applications is specifically designed for compounding and can be used in both automotive interior and exterior components.

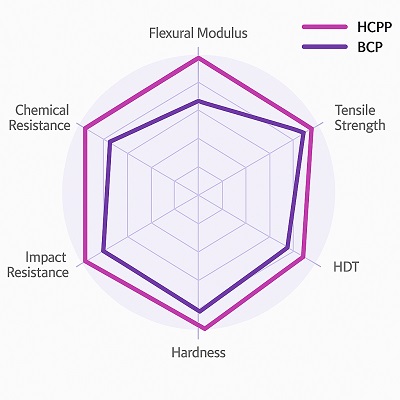

HCPP is ideal for automotive interiors due to its higher flexural modulus compared to general polypropylene materials, offering enhanced rigidity and durability.

RTPO is well-suited for automotive exteriors, such as bumpers, due to its superior impact resistance. Additionally, both

HCPP boasts higher flexural modulus, hardness, and gloss, making it suitable for applications like electronic housings. RTPO, with its high impact resistance and softness, is ideal for applications such as paint pails.

Hyosung HCPP (High Crystallinity Polypropylene)

Hyosung HCPP offers an exceptional balance of stiffness and impact resistance, along with

superior surface properties, heat deflection temperature (HDT), gloss, hardness, and chemical resistance.

HCPP can be compounded with minerals and polyolefin elastomer (POE) for use in automotive interiors. Additionally, its high stiffness, gloss, and hardness make it suitable for applications in furniture and electronic housings.

- Exceptional stiffness-impact balance

- Superior surface properties

- Excellent physical and chemical

resistance

Hyosung RTPO (Reactor Made Thermoplastic Polyolefin)

Hyosung RTPO exhibits exceptional impact resistance due to the polymerization of 35%

propylene-ethylene rubber (PER). The uniform distribution of the rubbers enhances its low-temperature impact resistance.

RTPO can be compounded with polyolefin elastomer (POE) and minerals, making it ideal for automotive exteriors, such as bumpers. Additionally, it is well-suited for applications that require high impact resistance, including plastic pails and roof finishing.